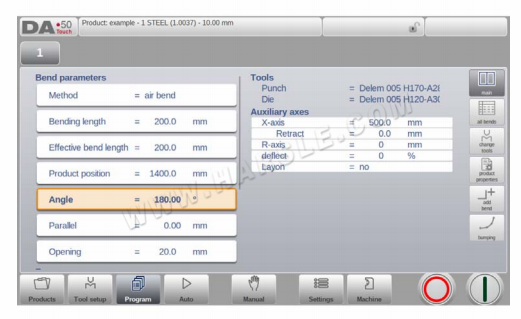

The software automatically unfolds the part and determines the optimum bend sequence by gauging positions, tool selection and set-up for minimum tool stations and part turns.CADMAN-L for laser. The production mode of the DA-58T helps the operator in graphically simulating the bend process of the product, guiding him during the press brake operation.Īdvanced Y-axis control algorithms for closed-loop as well as open-loop valves. LVD’s CADMAN programming software offers integration of the key sheet metalworking processes of laser cutting, punching and bending.CADMAN-B for press brakes makes programming formed parts easy. You are immediately ready to make the first part since all axes positions are automatically computed and the bend sequence has been simulated with machine and tools in real scale. CNC programs are generated with a single touch. Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence. Functions are directly located where needed, offering optimised ergonomics throughout the entire application. It enables direct navigation between product programming and actual production. Its 15" high resolution colour TFT, with industrial grade multi touch screen technology, gives access to the proven Delem user-interface.

Offering easiest CNC programming based on the Delem graphical touch screen user interface including automatic bend sequence calculation and collision detection. 0 Comments The Profile-T software program facilitates offline programming and simulation the twisting process.Production planning, makeability and tooling verification, user training, incorporating information for creation and several other features can be transported out offline.The tips from the start of. The DA-58T is a state of the art complete 2D graphical control solution for synchronized press brakes. Delem DA-58T Controller technical information for CNC hydraulic press brake in stainless steel sheet bending machine

0 kommentar(er)

0 kommentar(er)